Heli-Coil Inserts have evolved since their inception in the 1930’s and now

include the complete range of both tanged and tangless free running and

screw-locking wire insert systems.

Today Heli-Coil delivers a vast array of high quality inserts and installation tools designed to meet

the needs of the industry’s ever demanding designers and manufacturers. Inserts are available in

a variety of materials and special coatings. With Heli-Coil threads, tapped holes are strengthened

and thread life is dramatically increased.

Heli-Coil Inserts are The Original.

Manual Tools

Heli-Coil offers a complete line of tooling together with a

full array of STI taps, gages and tang break-off tools.

For production runs, prototype work, salvage and repair, Heli-Coil offers a range

of installation and extraction tools for both tanged and tangless inserts to

complete the needs of your application.

Power Tools

For higher volume production, we offer both electronic and

pneumatic power inserting tools.

Heli-Coil power tools can be adapted to assembly stations, rotary tables and

transfer lines for rapid installation. Our application engineers are always

available to assist in installation techniques and special tooling.

Quality

Our strict quality programs ensure that we meet the latest

industry standards of ISO/TS 16949:2002, ISO 14001:2004,

AS/EN/JISQ9100 Rev C and ISO 9001:2008. A comprehensive

Business Management System elevates our quality levels well

above our competitors.

Features & Benefits

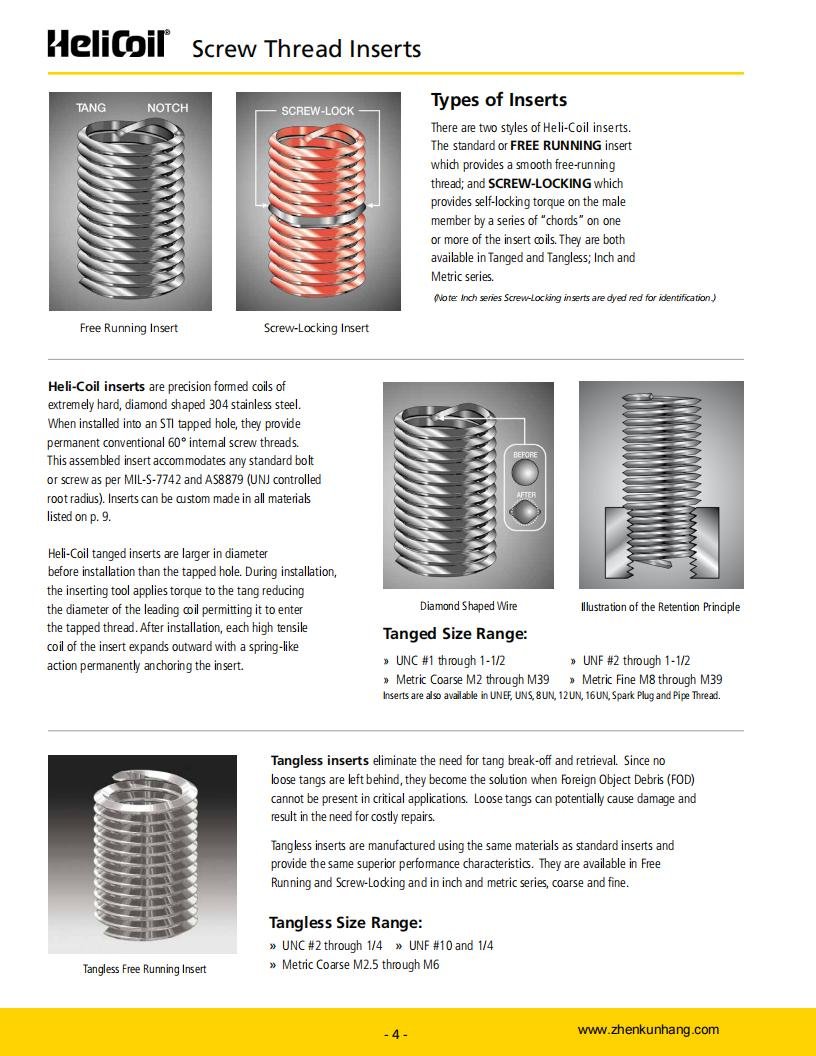

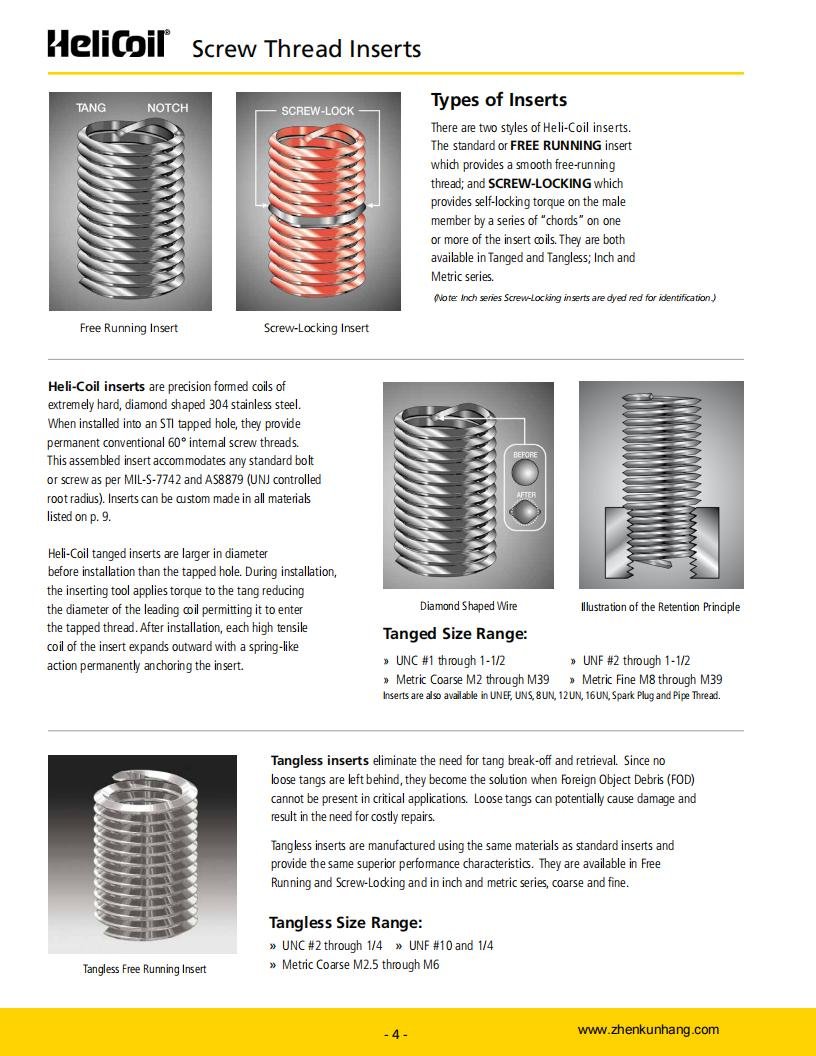

Heli-Coil inserts provide a positive means for protecting and strengthening

tapped threads in any material. The unique design features of the insert offer many benefits.

Stronger Assemblies

Tapped threads are strengthened because the inherent flexibility of the insert provides

a more balanced distribution of dynamic and static loads throughout the length of thread

engagement. This flexibility also compensates for variation in lead and angle error allowing each coil to carry its share of the load.

No Thread Wear

Thread life is dramatically increased even after repeated assembly and disassembly because the insert hardness and surface finish practically eliminate erosion of the thread form due to frictional wear.

Corrosion Resistance

Under normal environmental conditions, Heli-Coil inserts minimize galvanic action within the threaded assembly because of their superior corrosion resistance.

Design Flexibility

Bolt tensile strength can be balanced against parent material shear strength, assuring bolt failure rather than parent material damage. Five insert lengths are available in each thread size.

Eliminate Stress

Virtually no stress is introduced into the parent material because there is no staking, locking, swaging or keying in place – the outward spring-like action of the insert holds it in place.

Minimize Space & Weight

Heli-Coil inserts allow the use of smaller bosses and flanges than any other insert.

Heli-Coil inserts can generally be incorporated into existing designs, where no other provision has been made for an insert, without increasing boss size.

Minimize Total Cost

Cost savings abound. Lower insert cost, lower installation cost and Heli-Coil inserts provide design flexibility by allowing a wide choice of parent materials while maintaining maximum threaded assembly strength

True Clamping Torque

Maximum clamping action and bolt tension are assured with minimum wrench torque because of the mirror-smooth surface finish of Heli-Coil inserts.

Wide Temperature Range

Heli-Coil stainless steel inserts can be used in temperatures ranging from -320°F to +800°F.

Quality & Reliability

Stringent Quality Assurance and Engineering Standards are rigidly enforced in all phases of the manufacturing process. This assures integrity of your product design.

High Volume Production

Heli-Coil inserts are available mounted

on plastic strips and wound onto reels

(500 or 1000 inserts per reel). With power

installation tooling, use of strip feed inserts

will substantially increase installation rates

by minimizing handling.

Universal Acceptance

Heli-Coil Standard and Screw-Locking Inserts are the original – and have an extensive background of tension, torque, shear,

vibration and fatigue tests conducted by American industry’s leading companies as well as the U.S. Military. Successful

applications in the fields of aviation, electronics, industrial, automotive and military equipment provide a wealth

of experience and confidence in the performance and reliability of Heli-Coil inserts.

Custom Design Services

In addition to the benefits listed above,

Heli-Coil provides a wide range of support

to solve fastening problems. This design

catalog is one of them. The following pages

are presented in a manner to make it easy

to “design-in” Heli-Coil inserts to take

advantage of the extraordinary benefits

they provide.

Additionally, our Sales Engineers,

Applications Engineers and Design

Engineers are available for consultation

for specific designs. When the product gets

to the manufacturing phase, our extensive

experience in production tooling and

installation techniques ensures that you

can indeed make your product better

with Heli-Coil inserts.

Industry Standards

Heli-Coil inserts and tooling comply with the following Standards and Specifications:

NASM122076 thru NASM122275

Insert, corrosion resistant Helical Coil Coarse Thread

(Inch Series)

NASM124651 thru NASM124850

Insert, corrosion resistant Helical Coil Fine Thread

(Inch Series)

NASM21209

Insert, Screw Thread, Self Locking (Inch Series)

NASM33537

Insert, Standard Dimensions, Assembly (Inch Series)

NASM8846

Insert, Screw Thread, Helical Coil (Inch Series)

MA1565

Insert, Screw Thread, Helical Coil (Metric Series)

MA1567

Insert, Screw Thread, Helical Coil, Standard Dimensions, Assembly (Metric Series)

MA3279, 3280, 3281

Insert, Screw Thread, Helical Coil, Free Running

(Metric Series)

MA3329, 3330, 3331

Insert, Screw thread, Helical Coil, Screw-Locking (Metric Series)

AS59158

Tools for inserting and extracting Helical Coil Inserts

NAS1130

Inserts, Screw Thread, Helical Coil, Free Running and Screw-Locking (Inch Series)

NAS0276

Inserts, Screw Thread, Helical Coil, Free Running and

Screw-Locking (Metric Series)

FED-STD-H28

Screw Thread Standards for Federal Services

AS3094A; AS3094 thru AS3097

AS1229B; AS3080 thru AS3083

Special Locking Torque Inserts

ASME B18.29.1

Insert, Screw Thread, Helical Coil (Inch Series)

ASME B18.29.2M-2005

Helical Coil Screw Thread Inserts, Free Running and

Screw Locking (Metric Series)

AGS3600-3699

Insert, Screw Thread, Screw-Locking, Helical Coil,

Cadmium Plated (Inch Series)

AGS4677 Series

Insert, Screw Thread, Screw-Locking, Helical Coil,

Cadmium Plated (Metric Series)

AS6733

Inserts, Wire Thread, Unplated (UNF)

AS6734

Inserts, Wire Thread, Unplated (UNC)

AS8455

Inserts, Wire Thread, Cadmium Plated (UNF)

AS8456

详情访问: 320-Heli-Coil钢丝螺套.pdf