Sealing nuts and screws

■ Seals in the thread and below the nut

■ One-piece element, no extra assembly required

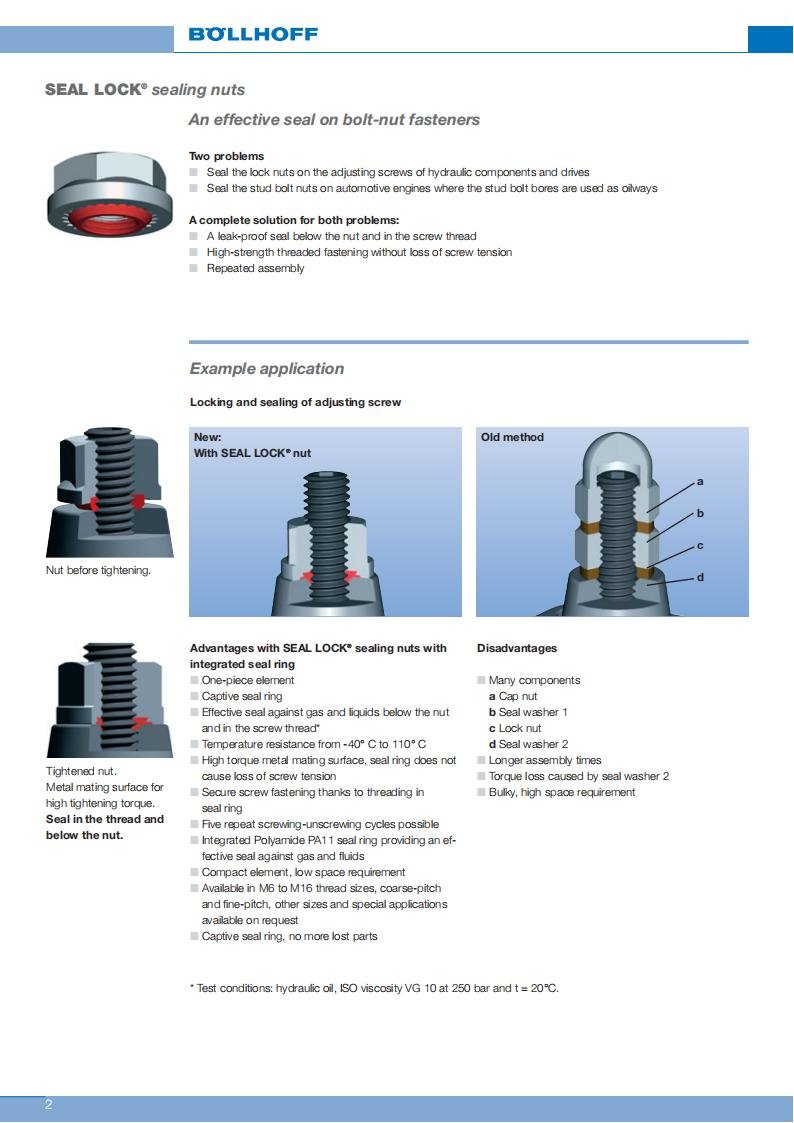

SEAL LOCK® sealing nuts

An effective seal on bolt-nut fasteners

Two problems

■ Seal the lock nuts on the adjusting screws of hydraulic components and drives

■ Seal the stud bolt nuts on automotive engines where the stud bolt bores are used as oilways

A complete solution for both problems:

■ A leak-proof seal below the nut and in the screw thread

■ High-strength threaded fastening without loss of screw tension

■ Repeated assembly

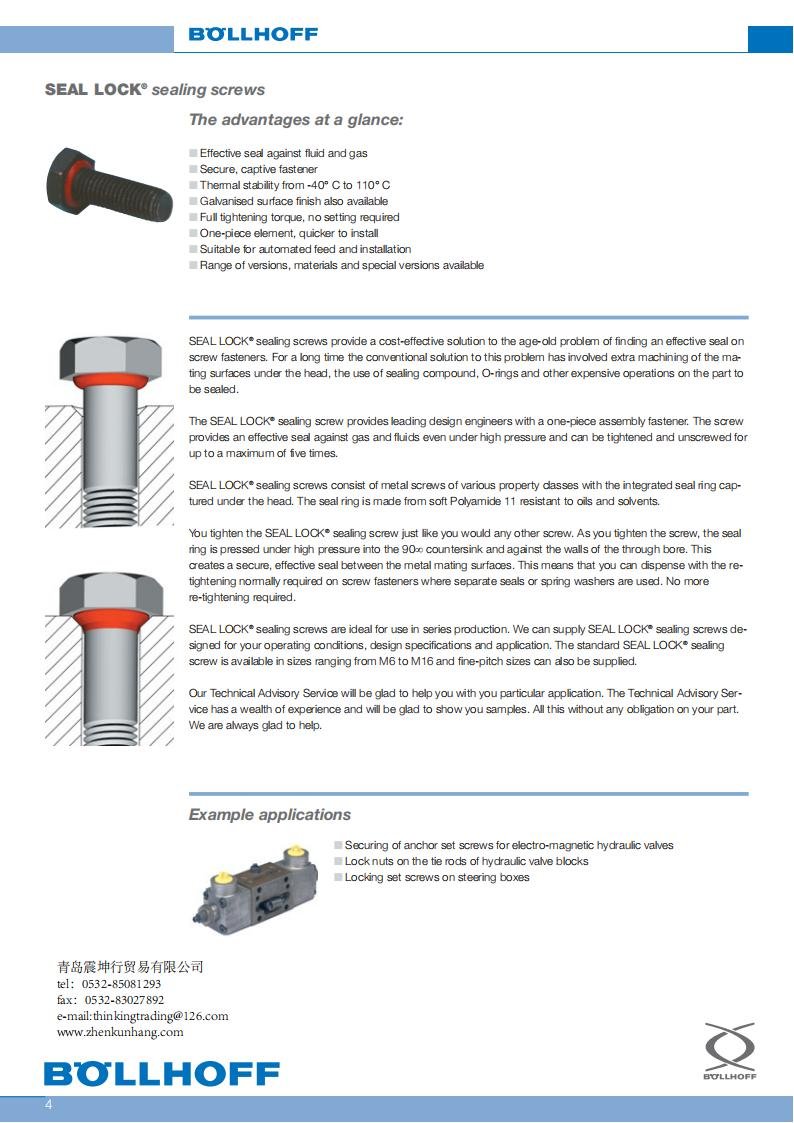

Advantages with SEAL LOCK® sealing nuts with integrated seal ring

■ One-piece element

■ Captive seal ring

■ Effective seal against gas and liquids below the nut and in the screw thread*

■ Temperature resistance from -40° C to 110° C

■ High torque metal mating surface, seal ring does not cause loss of screw tension

■ Secure screw fastening thanks to threading in seal ring

■ Five repeat screwing-unscrewing cycles possible

■ Integrated Polyamide PA11 seal ring providing an ef- fective seal against gas and fluids

■ Compact element, low space requirement

■ Available in M6 to M16 thread sizes, coarse-pitch and fine-pitch, other sizes and special applications available on request

■ Captive seal ring, no more lost parts

Disadvantages

■ Many components a Cap nut

b Seal washer 1

c Lock nut

d Seal washer 2

■ Longer assembly times

■ Torque loss caused by seal washer 2

■ Bulky, high space requirement

* Test conditions: hydraulic oil, ISO viscosity VG 10 at 250 bar and t = 20°C.

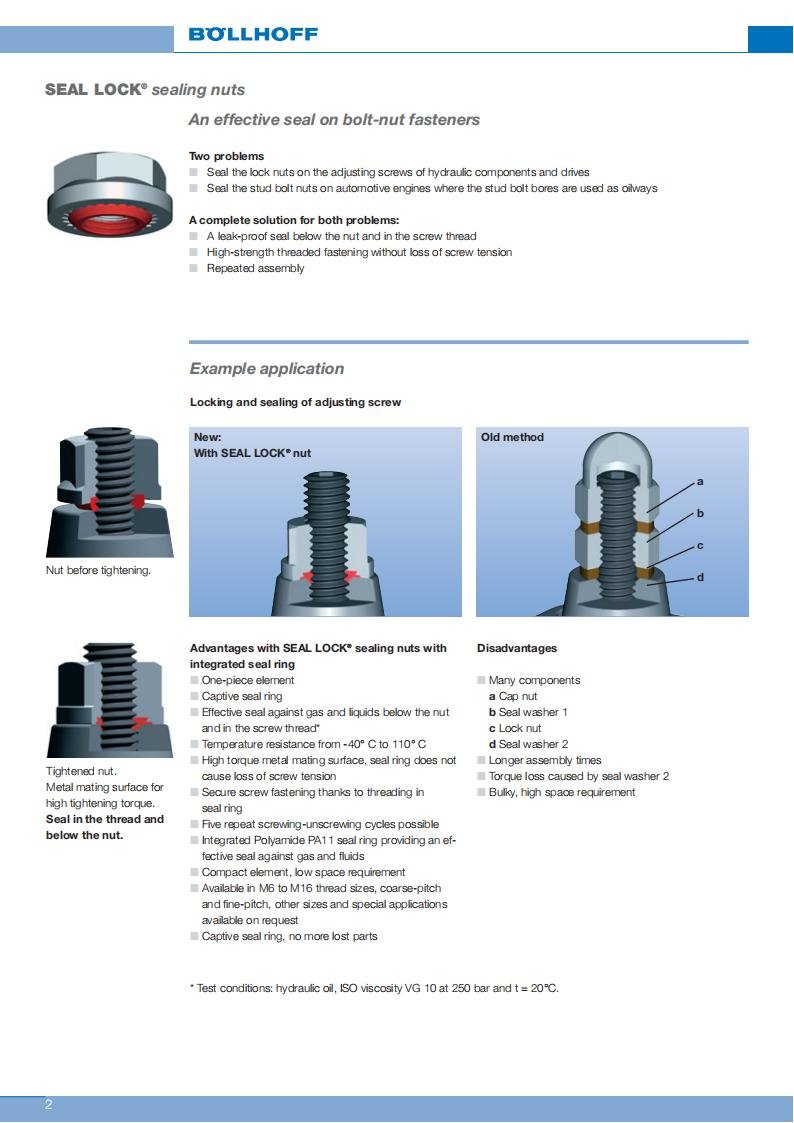

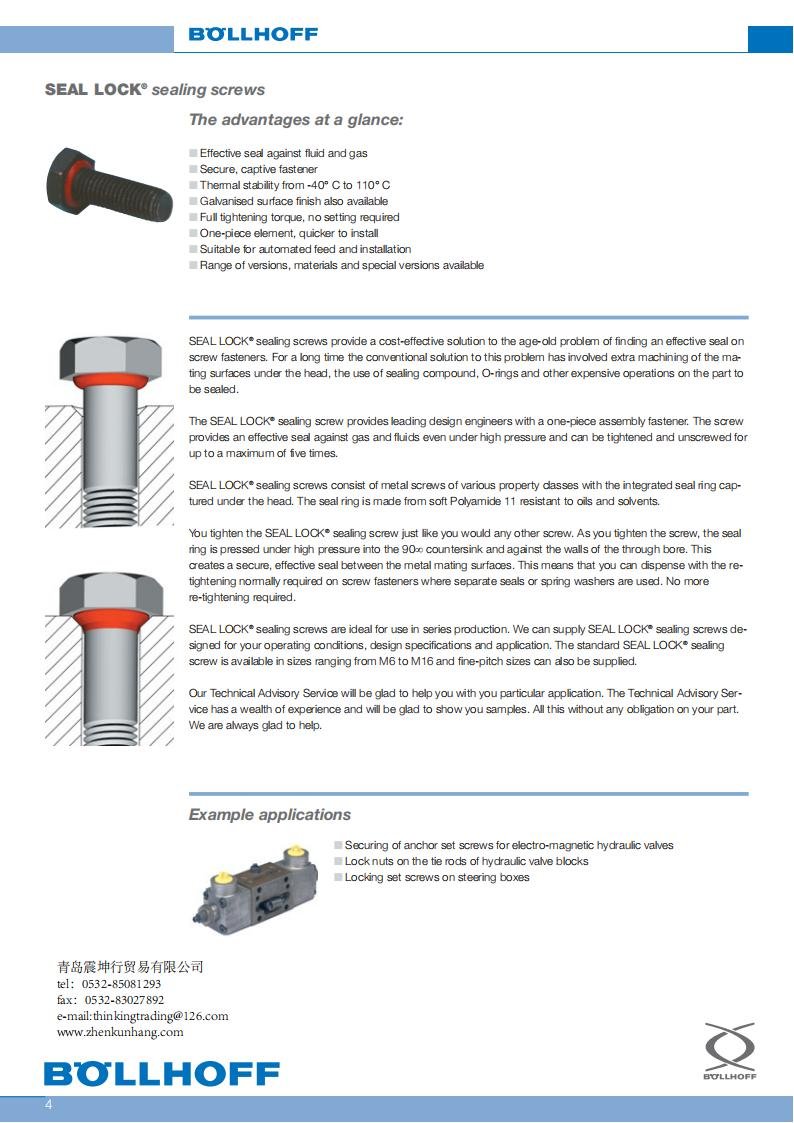

SEAL LOCK® sealing screws

The advantages at a glance:

■ Effective seal against fluid and gas

■ Secure, captive fastener

■ Thermal stability from -40° C to 110° C

■ Galvanised surface finish also available

■ Full tightening torque, no setting required

■ One-piece element, quicker to install

■ Suitable for automated feed and installation

■ Range of versions, materials and special versions available

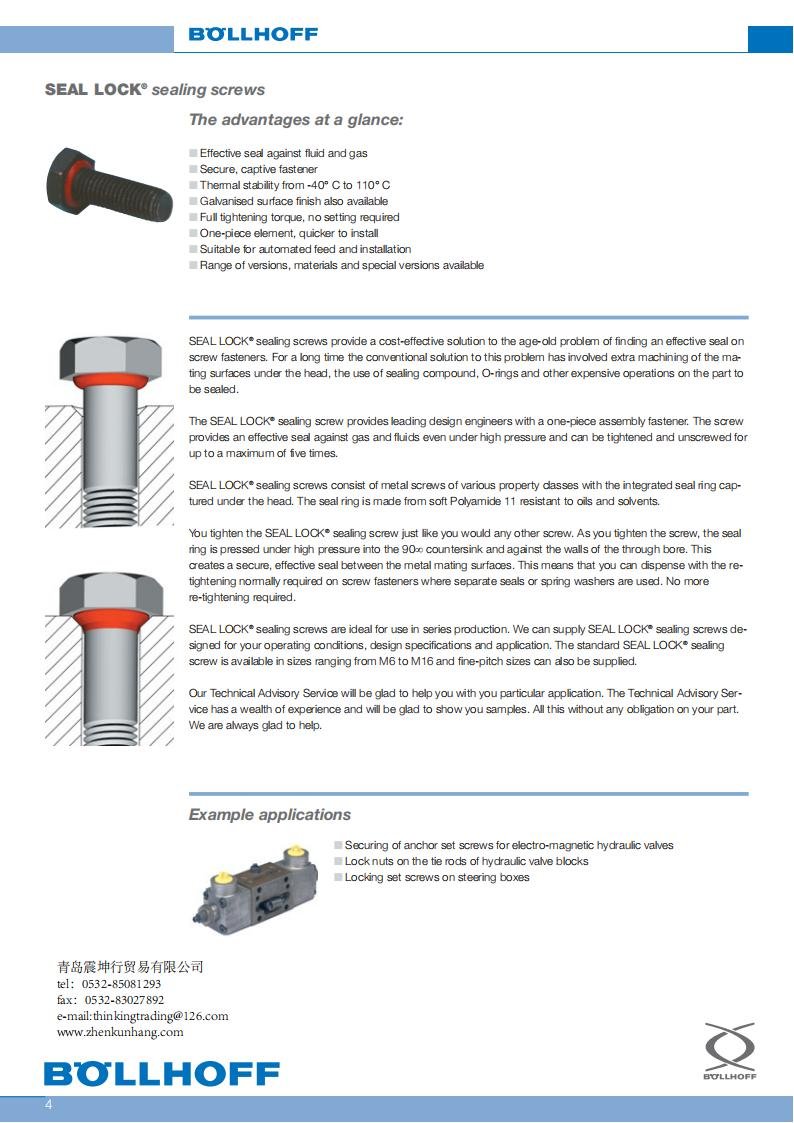

SEAL LOCK® sealing screws provide a cost-effective solution to the age-old problem of finding an effective seal on screw fasteners. For a long time the conventional solution to this problem has involved extra machining of the ma- ting surfaces under the head, the use of sealing compound, O-rings and other expensive operations on the part to be sealed.

The SEAL LOCK® sealing screw provides leading design engineers with a one-piece assembly fastener. The screw provides an effective seal against gas and fluids even under high pressure and can be tightened and unscrewed for up to a maximum of five times.

SEAL LOCK® sealing screws consist of metal screws of various property classes with the integrated seal ring cap- tured under the head. The seal ring is made from soft Polyamide 11 resistant to oils and solvents.

You tighten the SEAL LOCK® sealing screw just like you would any other screw. As you tighten the screw, the seal ring is pressed under high pressure into the 90∞ countersink and against the walls of the through bore. This creates a secure, effective seal between the metal mating surfaces. This means that you can dispense with the re-

tightening normally required on screw fasteners where separate seals or spring washers are used. No more re-tightening required.

SEAL LOCK® sealing screws are ideal for use in series production. We can supply SEAL LOCK® sealing screws de- signed for your operating conditions, design specifications and application. The standard SEAL LOCK® sealing screw is available in sizes ranging from M6 to M16 and fine-pitch sizes can also be supplied.

Our Technical Advisory Service will be glad to help you with you particular application. The Technical Advisory Ser- vice has a wealth of experience and will be glad to show you samples. All this without any obligation on your part. We are always glad to help.

Example applications

■ Securing of anchor set screws for electro-magnetic hydraulic valves

■ Lock nuts on the tie rods of hydraulic valve blocks

■ Locking set screws on steering boxes

详情访问: 429-SEAL_LOCK密封螺母.pdf